المعايير الفنية

| اسم | حدود |

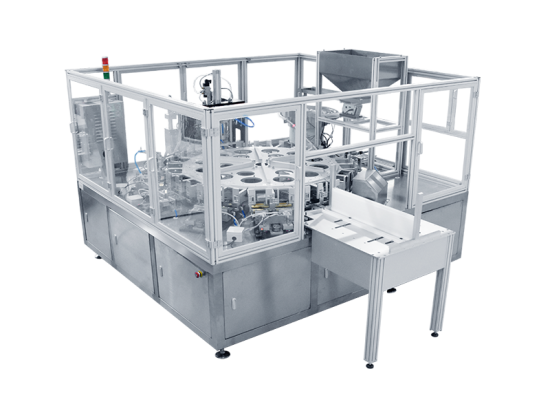

| الأبعاد الكلية | 5900 مم × 2650 مم × 1900 مم (الطول × العرض × الارتفاع) |

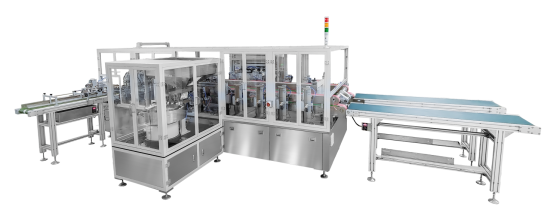

| أنواع التغليف | أكياس قائمة، أكياس محكمة الغلق من ثلاثة جوانب، أكياس معززة، أكياس بأشكال خاصة |

| أنواع المواد | - الأكياس: الطبقة الداخلية PE/PP |

| - الأنابيب: PE/PP | |

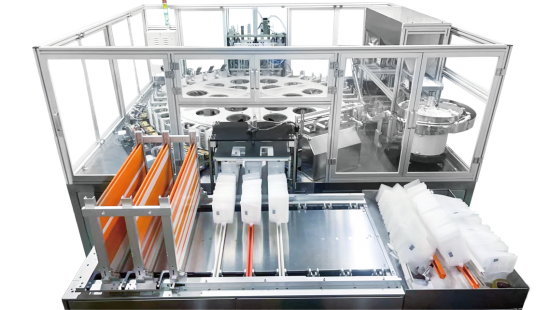

| مواصفات المنتج | - حجم الكيس: 150~350 مم (طول) × 120~250 مم (عرض)، طول الختم: 60~120 مم (قابل للتخصيص) |

| - أقطار القش: 8.5 مم، 10 مم، 14 مم، 16 مم، إلخ. | |

| سرعة العمل | 40-45 قطعة/دقيقة |

| دقة تحديد المواقع | ≤0.5 مم |

| أدوات الختم | إجمالي 6 مجموعات: ★1 التسخين المسبق، ★4 الختم الحراري، ★1 التبريد |

| وحدات التحكم في درجة الحرارة | مجموعتان (وحدات ذات 8 قنوات)، دقة ±0.1 درجة مئوية |

| درجة حرارة التدفئة | 0~300 درجة مئوية |

| مزود الطاقة | 380 فولت/50 هرتز، 3 نقاط + ن، 9.5 كيلو واط |

| إمداد الهواء | 0.6~0.8 ميجا باسكال، 280 لتر/دقيقة |

| وزن المعدات | 2000 كجم |

أ مجال التطبيق

|

|

|

|

كيس فوهة الجيلي |

كيس فوهة حليب الصويا |

حقيبة صنبور أدوات النظافة |

|

|

|

|

كيس هريس |

كيس فوهة على شكل خاص |

قابلة للطي في الهواء الطلق حقيبة الترطيب |

مميزات المنتج

تكوين النظام

info@gbtest.cn

info@gbtest.cn

ar

ar en

en ru

ru es

es