مقدمة:

تحتوي المواد البلاستيكية على نطاق واسع من التطبيقات، بما في ذلك في صناعات مثل الزراعة والبناء والتعبئة والتغليف وتصنيع الآلات. نظرًا لوزنها الخفيف، وقدرتها على تحمل التكاليف، ومقاومتها للتآكل، وسهولة معالجتها، أصبحت المواد البلاستيكية لا غنى عنها في العديد من القطاعات. ومع ذلك، أثناء الاستخدام، يمكن أن تتعرض المواد البلاستيكية للشيخوخة لأسباب مختلفة، مما يؤثر على أدائها وحتى يؤدي إلى تلف المنتج. وهذا أمر بالغ الأهمية بشكل خاص للمكونات البلاستيكية المستخدمة في البيئات الخارجية، مثل الألواح الخلفية الكهروضوئية أو أغلفة المعدات، والتي تتعرض لظروف قاسية مثل أشعة الشمس والمطر ودرجات الحرارة المرتفعة. إذا كانت هذه المواد تفتقر إلى خصائص كافية لمكافحة الشيخوخة، فإنها قد تفشل قبل الأوان. ولذلك فإن اختبار وتقييم مقاومة المواد البلاستيكية للشيخوخة له أهمية كبيرة.

1. الأغراض الرئيسية لاختبار أداء عمر المواد البلاستيكية

يقوم اختبار التقادم بتقييم متانة واستقرار المواد البلاستيكية في ظل ظروف بيئية مختلفة للتنبؤ بعمر الخدمة وأدائها في الاستخدام الواقعي. ومن خلال محاكاة العوامل البيئية المختلفة، مثل درجة الحرارة والرطوبة والضوء والأكسجين ووسائط محددة، يمكن تسريع عملية تقادم المواد البلاستيكية، مما يسمح بإجراء تقييم شامل لأداء تقادمها. تكمن أهمية اختبار أداء تقادم المواد البلاستيكية في:

- تقييم الثبات الحراري: اختبار ثبات المادة تحت درجات الحرارة القصوى لتحديد أدائها على المدى الطويل.

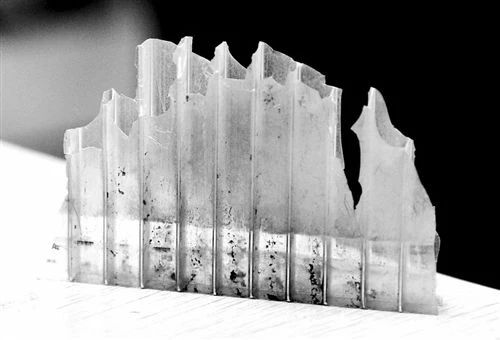

- تقييم تغيرات الخصائص الفيزيائية: ملاحظة التشوه والتقصف والتشقق وغيرها من الظواهر أثناء دورات درجات الحرارة العالية والمنخفضة.

- التنبؤ بعمر الخدمة: محاكاة البيئات الحقيقية للتنبؤ بمعدلات التقادم وعمر الخدمة في التطبيقات الفعلية.

- دعم تحسين المنتج: توفير البيانات لتحسين المواد وتحسين عملية الإنتاج، مما يساعد الشركات على تحسين جودة المنتج.

2. خصائص وآليات والعوامل المؤثرة في تقادم المواد البلاستيكية

- خصائص تقادم البلاستيك:

تشير تقادم البلاستيك إلى تدهور الخواص الفيزيائية والكيميائية والميكانيكية بسبب التعرض البيئي طويل الأمد أثناء المعالجة والتخزين والاستخدام. يمكن أن يحدث هذا بسبب الحرارة والضوء والإشعاع والإجهاد الميكانيكي والمواد الكيميائية والكائنات الحية الدقيقة. تظهر شيخوخة البلاستيك عمومًا في أربعة مجالات رئيسية: التغيرات في المظهر، والخواص الفيزيائية، والأداء الميكانيكي، والخواص الكهربائية. - آليات الشيخوخة البلاستيكية:

يمكن تصنيف الشيخوخة إلى شيخوخة كيميائية وفيزيائية. الشيخوخة الكيميائية هي نتيجة تغيرات التركيب الجزيئي في البوليمرات، وهو أمر لا رجعة فيه. ويشمل ظواهر مثل هشاشة المواد البلاستيكية وتكسير المطاط. تحدث الشيخوخة الفيزيائية عندما تتسبب عوامل خارجية في انتقال البنية الجزيئية للبوليمرات الزجاجية من حالة عدم التوازن إلى التوازن من خلال حركة مقطع السلسلة الموضعية، مما يؤدي إلى تغييرات في الخواص الفيزيائية والميكانيكية للمادة. - العوامل المؤثرة على شيخوخة البلاستيك:

تشمل العوامل الخارجية التي تؤثر على شيخوخة البلاستيك بشكل أساسي ما يلي:

- الإشعاع

- الأكسجين

- الأوزون

- الحرارة

- الرطوبة

- الإجهاد الميكانيكي

- عوامل أخرى

3. المبادئ الأساسية وطرق التقييم لاختبار تقادم المواد البلاستيكية

-

طرق اختبار التعرض الطبيعي:

يدرس اختبار شيخوخة الغلاف الجوي الطبيعي تأثيرات العوامل المناخية على المواد البلاستيكية عن طريق تعريض العينات إلى البيئات الخارجية. تتضمن هذه الطريقة تقييم مقاومة تقادم المواد عن طريق اختبار تغيرات الأداء قبل وبعد التعرض. يتضمن تقادم التخزين الطبيعي وضع عينات في غرف التخزين أو المستودعات في ظل ظروف مناخية طبيعية لتقييم أداء التقادم عن طريق قياس التغيرات بمرور الوقت. تضع اختبارات التعرض لمياه البحر عينات في بيئات بحرية مختلفة لتقييم أداء الشيخوخة من خلال تقييم التغيرات قبل وبعد التعرض.

تشبه اختبارات الشيخوخة الطبيعية إلى حد كبير ظروف العالم الحقيقي وتتطلب معدات بسيطة، ولكنها تتطلب مرافق كبيرة وفترات اختبار ممتدة. وتتأثر النتائج أيضًا بتقلبات الطقس، مما يجعل من الصعب قياس أداء الشيخوخة. تنطبق النتائج عادةً على مواقع تعرض محددة. -

اختبارات الشيخوخة الاصطناعية:

يتم إجراء اختبارات الشيخوخة الاصطناعية في المختبر وتشمل:

- اختبارات الشيخوخة الحرارية: تقوم هذه الاختبارات بتقييم مقاومة المادة للحرارة من خلال تعريضها لدرجات حرارة عالية أعلى من نطاق التشغيل العادي. يتم اختبار التغييرات قبل وبعد التعرض لتقييم الأداء الحراري.

- اختبارات الرطوبة والشيخوخة الحرارية: يتم تعريض المواد للهواء الساخن الرطب ويتم تقييم التغيرات قبل وبعد التعرض لتقييم مدى مقاومتها للرطوبة والحرارة.

- اختبارات التعمير الحراري للأكسجين والهواء عالي الضغط: هي اختبارات التعمير المتسارع التي يتم إجراؤها في درجات حرارة وضغوط عالية، مع استخدام التغييرات قبل وبعد التعرض لتقييم مقاومة الطقس.

- اختبارات شيخوخة الطقس الاصطناعي:تتعرض العينات لظروف بيئية خاضعة للرقابة تحاكي الضوء والحرارة والأكسجين والرطوبة والمطر. يتم اختبار تغيرات الأداء بسبب تشعيع السطح أو التعرض للإشعاع لتقييم مقاومة الطقس.

info@gbtest.cn

info@gbtest.cn

ar

ar en

en ru

ru es

es